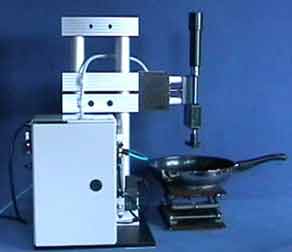

Scratch & Abrasive Tester for Non-Stick Cookware

- Allows non-stick coatings on flat surfaces (usually the inside bases of saucepans and frying pans) to be tested to BS7069, EN 12983 and Whitford test method 135C (also known as the Reciprocating Abrasion Test). Optional motor driven rotary axis can test to American Cookware Manufacturers Association Standards Manual test (clauses 21.1 and 21.2).

- The unit can be easily and quickly interchanged between the scratch test and the abrasion test.

- Fully automatic in operation, the unit can be set to the required number of cycles for each test and left unattended.

- Being fully adjustable in height allows the test unit to test both shallow and very deep items.

- Electrically powered motions with built in control system.

- The test equipment can be used with or without a suitable hot plate for carrying out the tests at cooking temperatures.

The scratch test is based on applying a hard pointed object (varies dependant on the test involved) under a fixed load and a controlled speed. After which the resultant damage to the surface can be assessed.

The abrasion test consists of oscillating a specified abrasive cleaning pad (such as a Scotch-Brite pad) along the non-stick surface again under constant load and speed conditions usually with a detergent solution added to the surface. Any surface damage or removal of coating can the be easily assessed.

The instrument can be used for checking the whole range of non stick cooking surfaces applied to saucepans, pans, bakeware, cooking pots, ovenware, baking trays, kitchen gadgets and utensils.